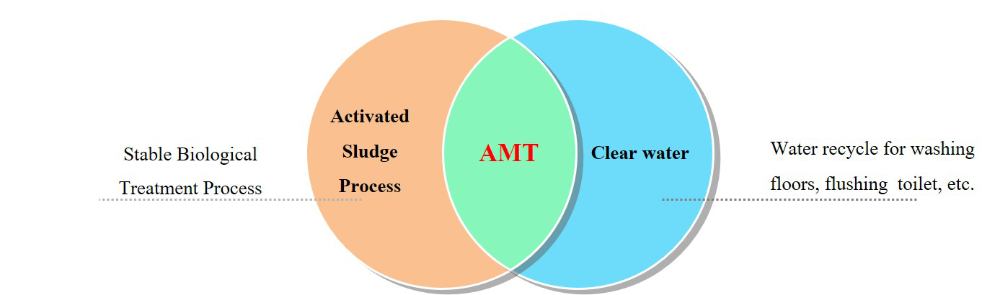

The FDC AMT innovation or Activated Sludge and Membrane Treatment is a combined utilization of microorganisms and powerful membrane filtrations to downsize the system while still maintaining its efficiency. The quality of wastewater that is treated through this system is higher than the water treated from the traditional AS system. The FDC AMT machine is the first stage of curing wastewater back to clean water. If customers wish to recycle this water into tap water or drinking water, they may do so by processing it in further steps.

Therefore, the FDC AMT system is highly recommended for customers in the industrial and agricultural sector as it does not only treat wastewater but also saves water resources.

Biological activated treatment system

Nowadays, environmental regulations are stricter than before. Businesses are also facing greater challenges and fiercer competitions to stay in the top ranks of the market. To do so, businesses must elevate their standards and be responsible in releasing clean and safe water back into the natural cycle and the society to lessen the impacts on the environment and help ease draughts or the shortage of water for consumption and usage in the agricultural and industrial sector.

One of the largest challenges for businesses in today’s world is the economic recession. As resources are valuable, to save production costs, Fusion Development Company Limited Activated Membrane Treatment (FDC AMT) was invented. This treatment system is highly effective in water treatment. It is also beneficial as it requires less space, saves energy, uses resources wisely, and is environmentally friendly.

Adhering to the 3R principle;

Reduce

Using lesser resources

Reuse

Using resources to their fullest extent and utilizing them again

Recycle

Treating wastewater and using it again in a repeated cycle

In terms of treatment effectiveness

● The BOD measured in wastewater is lesser than 7 mg/L.

● The turbidity is lesser than 1 NTU. After treatment, the water can be immediately reused.

● There are low values of excess sludge.

In terms of energy and expense saving

● The former system can be optimized without having to construct new structures.

● The membrane filtration set has a working span of over 10 years.

In terms of installation and space saving

● The system is easily controlled and maintained

● Requires less space; saves land and the expenses of building a large treatment system

● Can be installed at arid areas

● Quick, convenient, and easy to install

● All of the structure are manufactured and assembled at our factory to be successfully installed at the actual site within 1 week.

● If the user does not wish to use the system, it can be paused when not in use and can restart quickly to function again without requiring any expenses.

● The FDC AMT can be moved to work at other sites without being damaged.

Benefits

1. Treated water can be recycled into the water for plants, in restrooms, or upcycled into tap water.

2. Helps save hydro expenses and water treatment costs.

3. Can cure water for areas where freshwater is scarce, such as island resorts. There, seawater can be cured into safe, usable freshwater.

4. Saves the budget of building a new water treatment system.

5. Saves energy.

6. The system can be easily maintenance.

7. The treated water quality passes relevant standards.

8. Environmentally friendly and lessens water pollution problem.

9. Fortifies a nice caring brand image for the organization or establishment.

10. The surrounding community feels comfortable and at peace that they are safe.

FDC AMT is a cutting-edge technology used to treat and optimize the quality of wastewater with the combined benefits. It can be used to treat wastewater in many areas as follows;

Wastewater from communal areas;

commercial buildings, real estates, stores, restaurants, condominiums, office buildings, hotels and accommodations

Wastewater from industrial plants which can be divided

as follows;

● Wastewater from the food and beverage industry, e.g. sugar factories, tapioca flour factories, confectionary factories, rice noodle factories, food related factories, food processing factories, canned fruit factories, other food & beverage factories

● Wastewater from the industrial sector, e.g. milk factories, livestock farms, agricultural manufacturers, all agricultural relevant industrial plants, orchid houses

● Wastewater from the heavy industrial factories, e.g. chemical factories, automobile & spare part factories, casting factories, coating factories, spraying factories, medicine & chemical product factories, petrochemical factories, or wastewater from laboratories

For more information 02-115-8618

Fusion Development Company Limited is one of the greatest integrated industrial waste management service providers in Thailand. We specialized in coolants and used oil treatment and also provide waste and disused material disposal services.